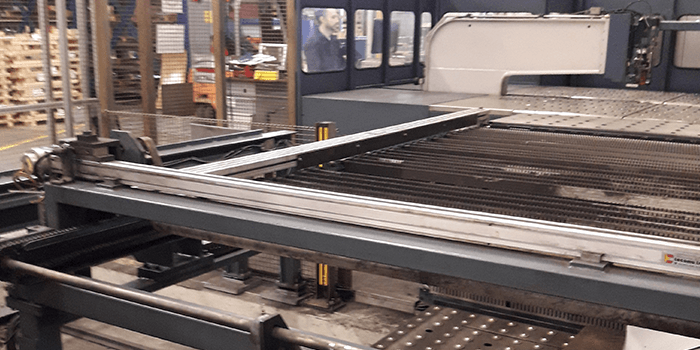

In many cases the chain driven brush conveyor, of the S4 Punching shearing system, has always caused problems on these machines. Brushes costing circa 25 euro each may need to be replaced on a daily basis, and the downtime required to keep fitting them is costly. The unload conveyor can finally be improved at a reasonable cost. Mink Bursten produce a modular belt package which is ideally suited for this application and we can supply the system fully fitted and tested by our engineers.

The continuous belts are far superior to the original chain and belt system supplied as standard on all S4 punching machines 1993- 2007.

Although Mink supplies the belts, we manufacture the pulleys, shafts and fixings to suit each machine. The installation requires substantial modifications to the support tables and expanding conveyor assembly.

The end result is worth every cent with lights out production running routinely.

Wildeman-Tec-Services bv

International Salvagnini Specialists

Breakdown and Servicing Machines

ONE CALL AND WERE ON OUR WAY.

In today’s competitive market, when your machinery stops working, you need a fast response. When all you need is to get an engineer to get the problem solved, one call and we’ll be on our way.

We know that when a machine is down the priority is speed of response and dedication to your problem until the machine is back in production.